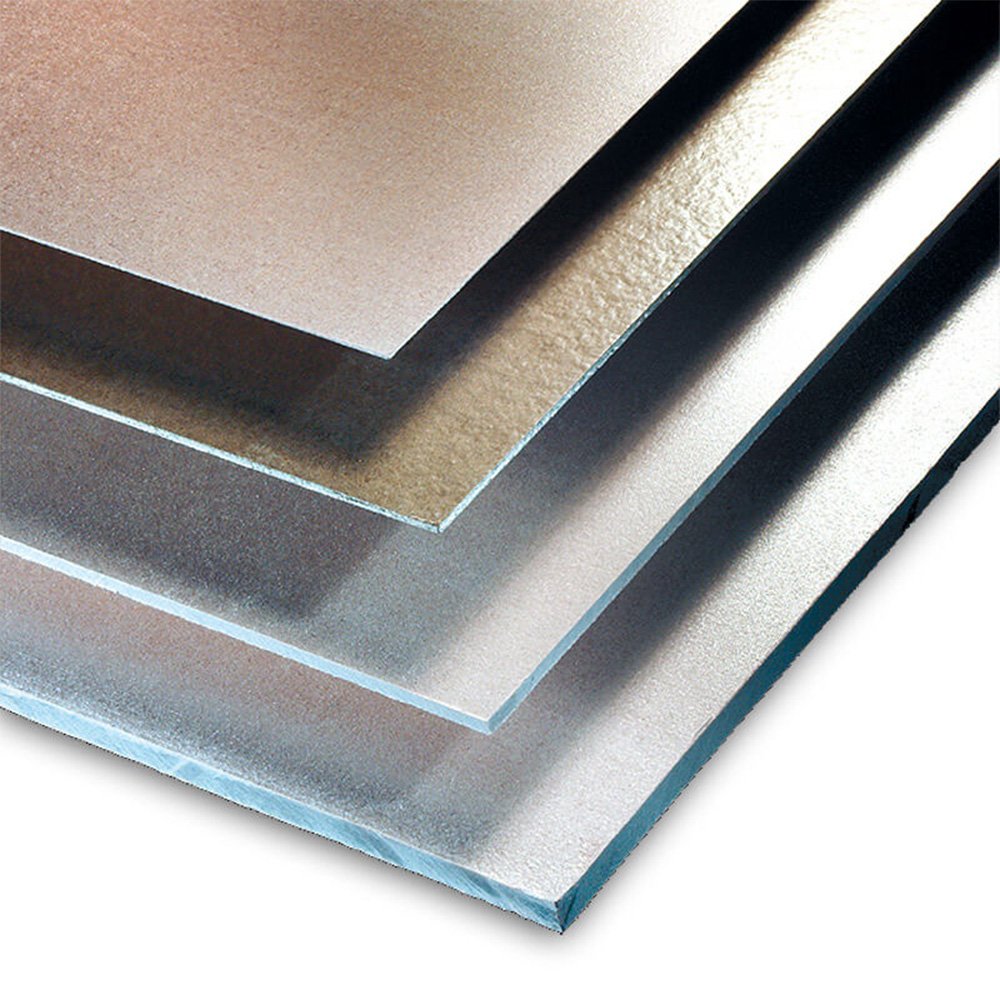

Refractory Mica Sheet

Mica is a natural mineral found in thin sheet-like structures. It contains varying concentrations of potassium, aluminum, iron, magnesium, and water. Due to its high density and suitability for high-temperature operations, mica is widely valued in industrial applications. Its excellent electrical, chemical, and mechanical properties have earned it a prominent place across various industries.

Two notable types of mica sheets—rolled mica and rigid mica—are distinguished by their unique characteristics and industrial relevance. Below is a closer look at each type:

Rolled Mica

Definition & Properties

- Rolled mica is manufactured in flexible sheet form, typically supplied in rolls.

- Its high flexibility and ease of handling and installation make it a preferred choice in many applications.

- The layered structure provides excellent thermal resistance and electrical insulation.

- Standard roll dimensions allow for easy cutting and resizing to suit diverse requirements.

Applications

- Electrical Insulation: Used for wrapping and protecting coils and cables due to its insulating properties.

- Electronics Industry: Ideal for components requiring flexible, heat-resistant materials, such as thermal conductors.

- Construction: Applied in thermal insulation for centralized heating systems and heat tunnels.

Rigid Mica

Definition & Properties

- Rigid mica is produced in stiff, inflexible sheet form, offering lower flexibility compared to rolled mica.

- It exhibits high resistance to heat and electrical shock, making it suitable for demanding environments.

- Superior Thermal Stability: Maintains performance under extremely high temperatures.

Applications

- Thermal Insulation: Used in furnaces and industrial units requiring extreme heat resistance.

- Mechanical & Electronic Engineering: Suitable for components that require a fixed, stable form.

- Industrial Appliances: Found in welding machines and high-pressure equipment that demand both thermal and electrical insulation.

Comparison & Conclusion

Both rolled and rigid mica sheets serve distinct purposes across industries. Rolled mica excels in flexibility and ease of use, making it ideal for broad applications. Rigid mica, on the other hand, is preferred for situations requiring structural integrity and high durability. The choice between the two depends on the specific project requirements and environmental conditions.

Ultimately, both types of mica sheets are valued not only for their thermal and electrical insulation capabilities but also for their resistance to various chemical processes. If you require further information or have specific questions, we would be pleased to assist you.